Since 1901 the Ashburton-based New Zealand Sock Company has been manufacturing quality merino wool socks for the nation’s feet – and more recently, for feet all over the world. It’s one of our most enduring and inspiring export business stories.

By Glenn Baker.

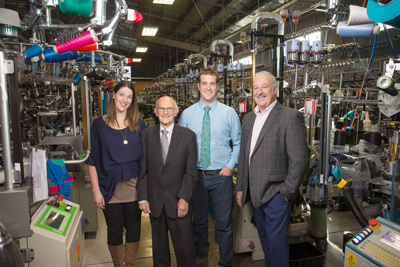

The New Zealand Sock Company needs little introduction. There are very few of us who have not wriggled our toes into a pair of its comfy high-tech creations. For a company that’s been around for 115 years, and spanned three generations of the Sparrow family, it certainly has staying power.

In recent years much of that success, particularly on the export front, can be attributed to its adoption of clever manufacturing technology.

CEO Euan Sparrow, who bought the business with his dad Cip in 1980 has recently described The NZ Sock Company as “the world’s highest-tech sock manufacturer”. A lot of that is to do with the recent investment in the latest leading-edge plant from Italy – but the technology doesn’t stop there.

“We don’t just sell socks anymore, we are selling technology,” explains Euan. “We developed a bridging system with a world renowned diabetes specialist podiatrist, having spent a number of years researching and finding out about feet and what is needed to protect them. From this, came our patented Paladin™ Protection Pad.”

This technology is now the catalyst for all the company’s growth moving forward, he says.

“We now offer our technology, along with that of The Merino Company’s NuYarn®. This is a revolutionary technology that has changed the apparel industry.”

Such leading technology is crucial to building sales in offshore markets, he believes. “To make money in the export market, you need to offer something that is of high value and like nothing else out there. Anyone can make a sock, but we offer more than just a sock.”

The company’s first export business was to Canada and the UK in 1994, which Euan describes as being “a very exciting time”.

“Unfortunately back then we never had the marketing experience or funding to really get it off the ground. The product we were showing was obviously different to what we are doing now, but it was still a high quality woollen sock made in New Zealand. At the time there were no other New Zealand-made socks in those markets.”

The export strategy today is vastly different. Now it’s about getting recognised in the international market – developing and making socks for some of the world’s leading brands.

“Brands we currently knit for are KUIU, Norrskov, Kathmandu, RMW Williams, The North Face and Ortovox, to name a few,” says Euan. “They understand our brand and technologies and what we can offer.”

It would be fair to say manufacturing apparel locally for export flies in the face of almost every trend within the sector in New Zealand. So why has The NZ Sock Company been so successful?

Euan puts it down to the technology, the R&D, and the company’s loyal staff.

He does point out that they have some product knitted offshore. “We have a factory in China that makes price-focused product for some customers in the domestic and international market.

“And I guess if I was honest, it does help subsidise our manufacturing in New Zealand,” he admits.

“However, the margins that we achieve from our export customers far exceeds what we receive in New Zealand, as this is driven down by big box retailers.”

Growth strategy

The company’s strategy going forward is based on growing within its capabilities and not over-stretching its resources. “However, we do have a machine replacement policy that every year we purchase new plant, whether we can afford it or not,” says Euan. “This has given NZ Sock the advantage of having one of the most modern plants in the world, thus giving us and our customers a leading edge over their competitors.

“We recognise our competitive strengths – which are our technologies and IP – and we export to Japan, the US, Australia, Denmark and Germany. Brands that we contract knit for have distributions in more than 26 countries. So really, we should be saying that we have NZ Sock-made socks in more than 30 countries!”

The NZ Sock Company generally does its own research on new export markets first by spending time in the countries it wants to sell into.

“Then we engage the help of NZTE for further research and development funding,” says Euan.

“A joint marketing approach with key suppliers has also helped us gain traction into some desired markets.”

As for offering advice in what is regarded as a highly competitive apparel sector, Euan says export initiatives should be combined with your company’s overall business plan. “Align export activities with your daily operations and avoid any conflicts between your domestic and international activities,” he advises.

Understand the areas where you have a strong competitive advantage, he says. “These areas may include your technology or your staff. Determine how best to place them to achieve your goals.

“Also identify any weaknesses and work to overcome them. Focusing your resources enables you to provide quality responses and service to your new customers.”

For a company that’s been around for so long, things are not about to slow down for this Ashburton manufacturer. But when pushed to reveal what other new initiatives the company has on its drawing board for 2016 and 2017, its CEO was keeping some cards close to his chest.

“Now that would be telling! I can say that we are working on some very exciting projects with some major offshore brands in the sports and military markets,” says Euan.

That’s more history in the making.