A New Zealand company has developed and launched an innovative filter media for face masks and air filtration systems that kills bacteria and viruses, including the Human coronavirus 229E.

Auckland based company NanoLayr, a deep tech manufacturer specialising in nanofibre production at scale, has added manuka oil to its patented nanofibre filter product FilterLayr, to create a N95 rated filter media.

The properties of the manuka as well as the high surface area of the nanofibres, means that FilterLayr is one of the most effective filter media in the market.

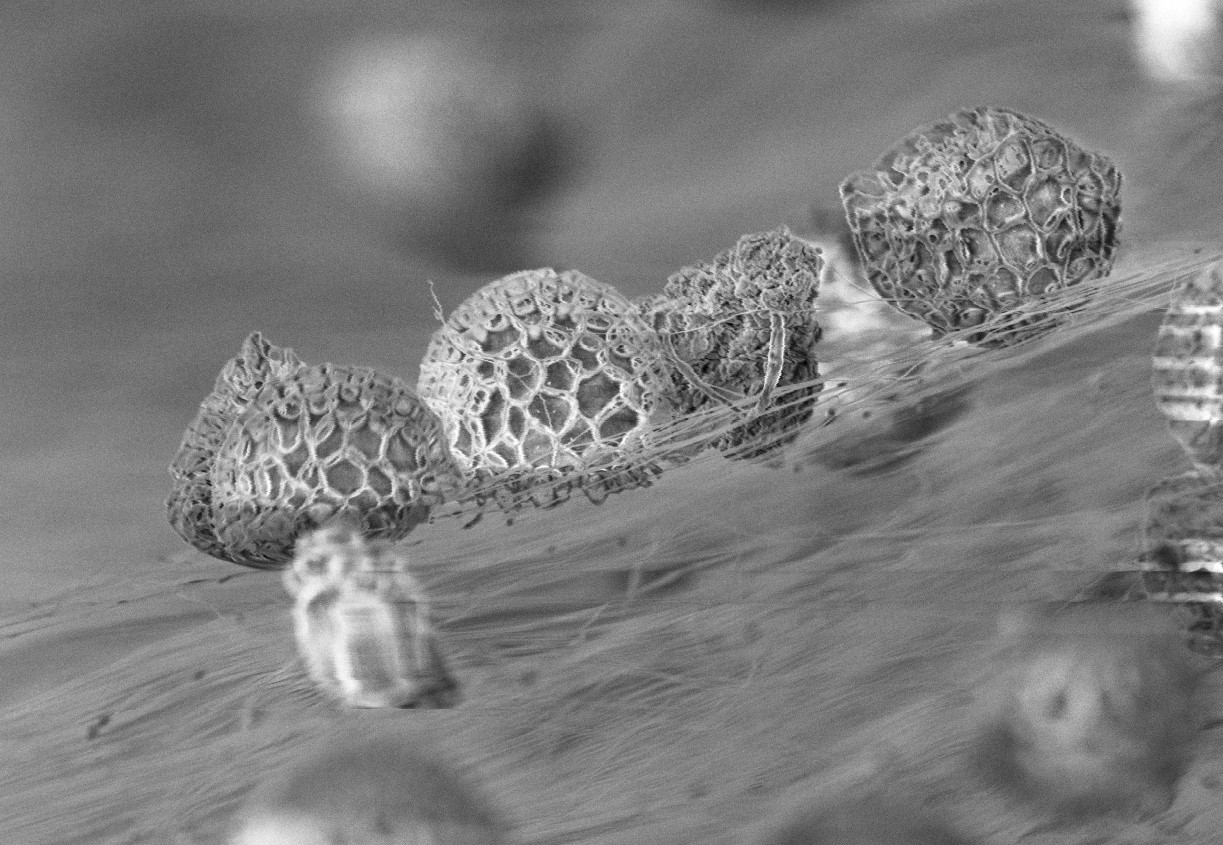

NanoLayr testing has shown FilterLayr with manuka infused nanofibres kills >99% of bacteria as well as bacteriophage. Independent testing has also shown FilterLayr to be effective in killing/inhibiting the COVID-19 surrogate virus, Human coronavirus 229E and further testing on similar viruses such as Covid-19 is underway.

NanoLayr CEO Ray Connor (pictured below) says the development is a breakthrough in the fight against future pandemics, as FilterLayr can be produced at large scale to help meet global demand for face masks.

“The pandemic has highlighted the importance of providing effective protection for workers on the front line and the large numbers of people who wear masks daily. The beauty of this product is that it provides highly effective protection against infectious bacteria, viruses and airborne particles,” he says.

NanoLayr is the first manufacturer to use manuka oil as a microbial agent in air filtration applications. The bioactive manuka oil is contained within a nanofibre fabric that stops viruses and bacteria from passing through it, meaning any bacteria or virus trapped in the nanofibre fabric are deactivated and killed. This delivers a far superior result to filters coated with bactericidal actives, where the active coatings can wear off and risk entering the users body.

Connor says the bioactive nanofibre filters can be used in facemasks to not only greatly reduce the possibility of contamination and infection, but it also results in a more sustainable product.

“The nanofibre used for these filters is made from specific polymers that are effective at absorbing and carrying active ingredients like manuka. The nanofibre enables the controlled release of these actives over a prolonged period, meaning masks can be worn for longer, they can be used multiple times, and they provide a better experience for the person wearing it,” says Connor.

NanoLayr supplies filtration media to multiple overseas face mask manufacturers, including HALO Life in the US, and HVAC systems to local home solutions company HRV.

FilterLayr was developed with investment by NanoLayr as well as a $950,000 contribution from the Ministry of Business, Innovation and Employment’s Covid-19 Innovation Acceleration Fund (CIAF). CIAF was set up last year to support New Zealand’s response to meet global and local PPE (Personal Protective Equipment) demand.

Connor says NanoLayr’s FilterLayr platform will also support future pandemic responses and the company is currently upscaling production of the new product.

“We have developed incredible platform technology that is leading the world in the production of nanofibre. We have a focus on using our technology in a way that we can make a positive impact on the lives of as many people as possible.

“For us, this development of FilterLayr was the right thing to do, not only does it have the ability to benefit frontline responders, but as a novel media, it will also help put New Zealand at the forefront of the global textiles industry and establish the country as the centre of excellence for nanofibre.”

Main image: Virus particles captured and killed by NanoLayr’s filter media.

NanoLayr manufactures functional fibres that improve the quality of life for their users. For use within a diverse range of sectors across the globe, including filtration, skincare, sound insulation and structural strengthening in Formula One cars and the aerospace industry. Scale manufacturers, NanoLayr lead the commercialisation of nanofibre technology in New Zealand with product lines such as air filtration for HRV Next Generation ventilation systems, high-performance carbon fibre reinforcement products and high frequency acoustic insulation.

Nanofibres are textiles made from superfine fibres between 100-500 nanometres in width (1/500th the width of a human hair). These small fibres can create vast changes in mechanical strength, reactivity, and conductivity, among many other properties.